Beta Automatic Clipping Machine

Clipping machines with automatic sealing for the production of meat products. Equipment with high productivity and low maintenance cost.

With our engineering department, we developed the Beta Automatic Clipping Machine that enables parts to have a longer life span and more efficiency in production. We work with the best available options for each technical partner to deliver high quality standard solutions to our customers at a competitive price.

Beta Machine

Machine

Technology

Maintenance

Support

Machine technical Specifications

The Beta Automatic Clipping Machine is used in the production of different meat products, such as mortadella, salami, ground beef, black pudding, regular sausages, U-shaped sausages, among others.

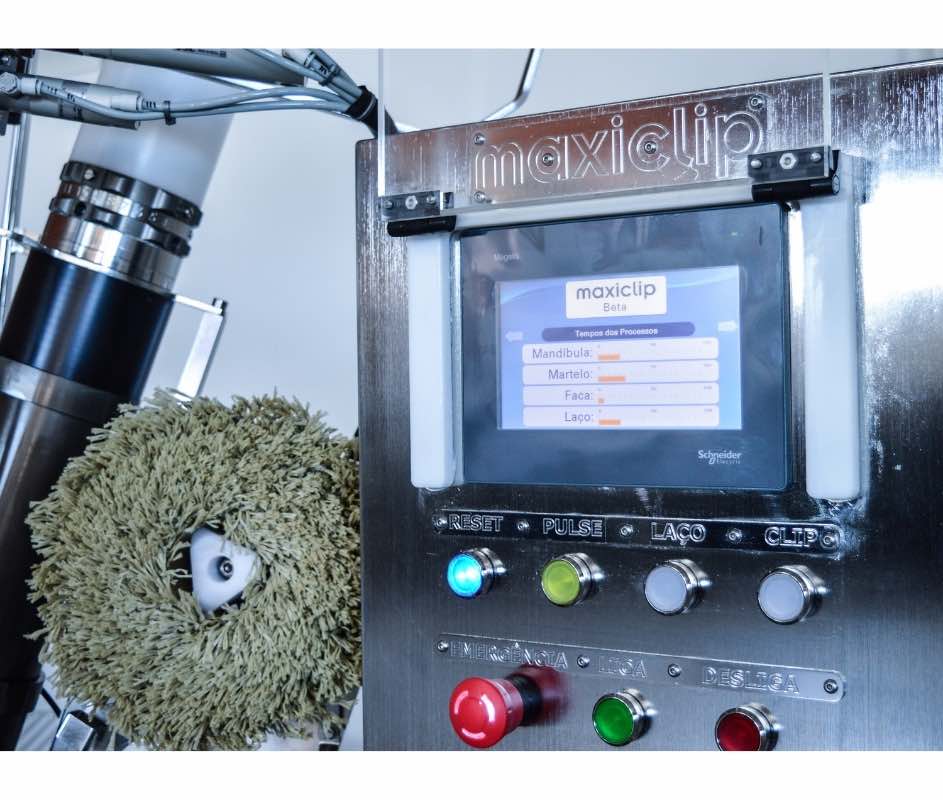

It is equipped with an electronic command that allows the connection between it and the filling unit. The connection of the filling flow points between both equipment takes place through mechanical connection.

The machine’s automatic duty cycle will clip the end of the freshly filled product, and in the same process, seal the beginning of the next product. The separation cut between products also occurs automatically, and this separation can be programmed to happen after the filling of each product unit or after filling a series of sausages.

This way, it is possible to continuously produce individual units or chain filling. You can also program the placement of loops on individual units of the meat product (Charcuterie) or via chain looping.

Beta Machine Characteristics:

- Its clipping capacity includes gauges between 25 and 85 mm, using serial clips;

- Equipment suitable for clipping nylon, natural, fibrous, cellulosic, plastic packaging, among others;

- The equipment’s operating temperature ranges from 0°C to 55°C;

- Machine dimensions can vary according to installation conditions: height = 1880 – 2130mm, length = 1753mm, width = 2000 – 2400mm;

- Equipment weight without packaging: 120 kg;

- Air pressure: 4 – 7 bar or 0.4 – 0.7 MPA;

- Compressed air consumption per duty cycle: 17 liters;

- Supply voltage: 220/110V;

- Energy consumption: 1.1kWh for 110V and 2.2kWh for 220V;

- The machine is fully compliant with Brazil’s NR12 safety standard.

How to buy the Maxiclip Beta Automatic Clipper

Get in touch with our commercial team so that we can understand your business requirements and demands, and submit a proposal. Upon customer approval, our service team will schedule the delivery, installation and, equipment training.

Support and technical assistance are provided by telephone and, when required, in person, as agreed with the customer.

Let’s talk about Clippers for your Business?